We work for

the environment and

the planet

Our commitment to Sustainability

Our vision is deeply rooted in the fact that everything we do for any stakeholder has only value if it can be done in a perennial way. This means that we only use resources that we do not contribute to deplete, that we preserve the nature around us, that we maintain the skills of our employees and cultivate those of tomorrow, and that we strengthen our economic strength.

To achieve all these ambitions, we use a comprehensive management system that ensures that we consider all the possible impacts of a project or change, that we analyze any deviations and eliminate their causes, and that we continuously measure and improve our performance. We spend a lot of time and money on this and are collectively proud of it.

Environment

Like any plant, our industrial activity has interactions with our environment: we use and reject water and air and generate some noise.

From more than 20 years we have been measuring it and containing it within an accepted level for our neighborhood and the natural environment around us. Not only do we strive to meet our regulatory thresholds, but we maintain our wastewater discharge well below our obligation, thanks mostly to our many in-process recycles.

Besides these regular interactions, we have exhaustively analyzed all possible deviation scenario that could have an excessive effect on the environment and have reduced them both in probability and impact. We also aim to reduce our use of plastic, in our industrial activity and in our professional life.

Energy

As every fermentation site, our plant is using a lot of energy such as steam, electricity and cooling power.

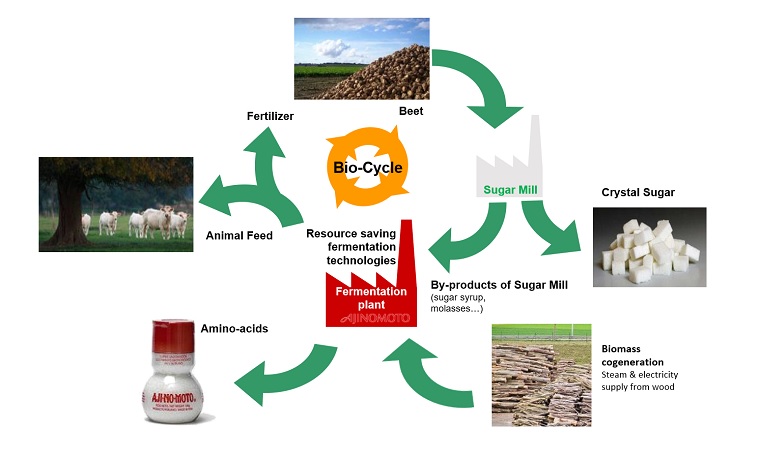

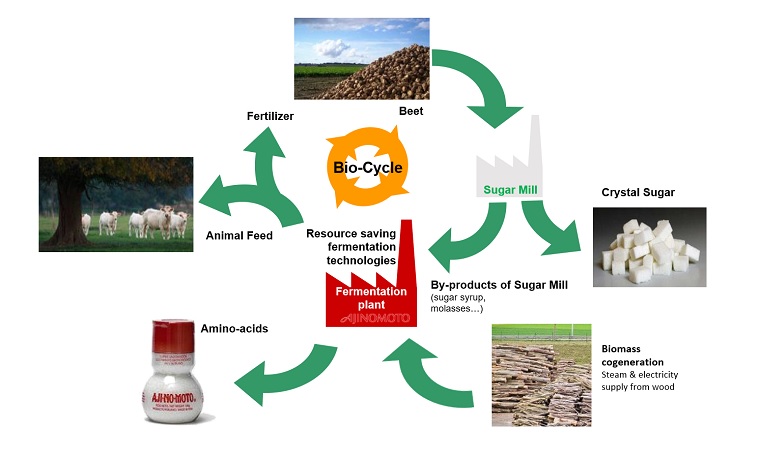

Our largest move to reduce our use of fossil energy and decrease our carbon footprint 10 years ago was to participate to the construction of a biomass cogeneration plant that supplies us our steam and enables us to use 75% renewable energy. In addition, since 2015, we have initiated a continuous improvement of our energy impact, using ISO 50001 methodology: we have measured all our consumption, identified the most significant ones, improved their control, and implemented every year some reductions.

Thanks to the skill and devotion of our manufacturing, maintenance, and engineering teams, we benefit from a 2% to 5% reduction in our consumption each year.

Integration

We are proud to be completely integrated in the agricultural and industrial activity of our area.

Long before Ajinomoto purchases the asset, the first plant was built in Nesle 150 years ago because it could use the crop of the neighboring fields. Our fermentation substrates come from local sugar or glucose factories, and our energy comes from sustainably managed forests of close regions. Our co-products are going back to the world of farming, as some of them are base material for the manufacturing of fertilizers, while other ones are used for animal feed.

We also welcome every year many interns in various fields, which completes our commitment to be integrated in the local community.

We are certified